Slag removal – economically clean oxyfuel and plasma cut parts with profiRounder by Heesemann

Oxy-fuel & plasma cutting score with convincing cost-effectiveness. The disadvantage is that burning slag and strong burrs are created. Our profiRounder can remove this slag economically with its RUT unit using slag chipper brushes.

Automatic slag removal

There are two basic ways in which slag can be removed. On the one hand, this can be achieved with a grinding process. Then very coarse abrasive grains K24 / K36 are used and the (often more than one) contact rollers are designed to be very soft. On the other hand, slag can also be knocked off. The advantage of this second variant: Less grinding effort and the grinding belts are protected! The trend today is therefore more and more towards not removing slag with the grinding process, but simply knocking it off.

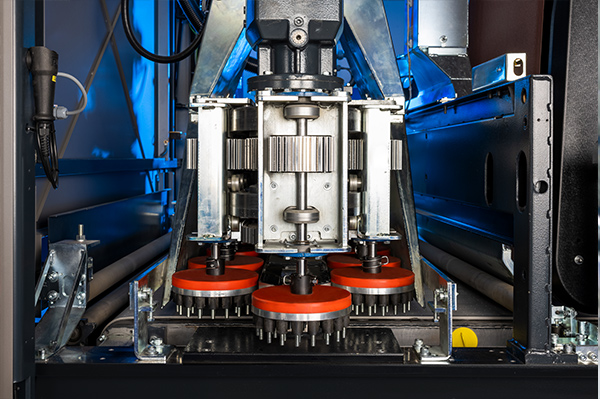

Using hardened steel pins to remove the slag

Hardened steel pins that are vulcanized into a cup brush have established themselves as an efficient tool for removing slag and dross.

Since the workpieces are often warped, it is necessary to have the cup brushes working with the hardened steel pins from above. The tools are set in such a way that they do not hit the workpieces laterally, but only touch the slag that stands up. Remaining burr formation is removed with a subsequent wide-belt unit.

The profiRounder: Expert in slag removal

With the profiRounder, we offer you a machine solution with which slag removal can be optimally implemented. The machine scores with high flexibility, which also shows its advantages when it comes to slag removal. Depending on the requirement profile in your company, you can use the profiRounder as required and therefore always tailor-made. It pays off – also in solid work results for an extra plus in customer satisfaction. By means of a RUT unit running with cup brushes with hardened steel pins, slag processing can also be integrated and ensures optimal processing of your workpieces.