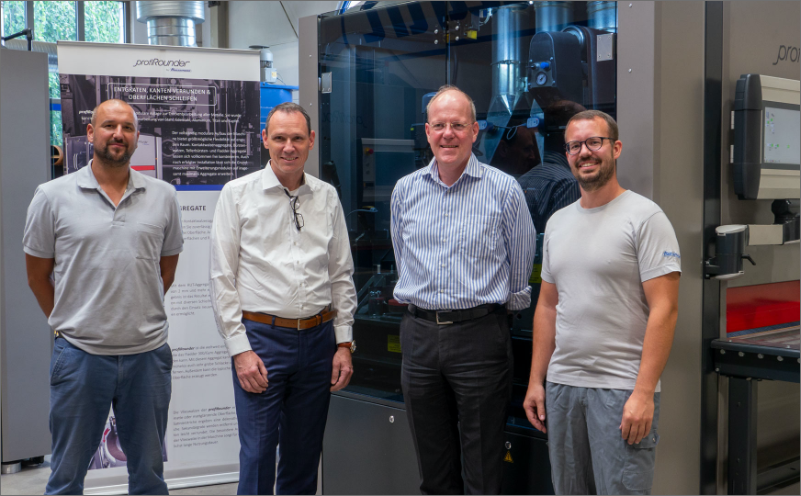

Heesemann continues to expand its commitment to deburring technology

From August 17, 2020, Markus Lindörfer will take over the deburring technology division at the grinding machine manufacturer Heesemann. The long-established company from Bad Oeynhausen in Westphalia is thus underlining its ambition to further strengthen its commitment in the field of metal processing in the future.

The qualified computer scientist and industrial engineer Markus Lindörfer brings almost 20 years of experience with Paul ERNST Maschinenfabrik – first as sales manager, then later as managing director and managing partner of the deburring machine manufacturer from Kraichgau. As an independent specialist and consultant, Lindörfer has been a valuable source of ideas for many companies in the industry since 2017. With the commitment at Heesemann, he is now returning to his professional roots.

Excellent grinding results were decisive

Above all, the quality of the machines and the excellent grinding result were the reasons for this decision. “Heesemann has succeeded in developing machines with which one hundred percent uniform rounding results can be achieved. This is not the case with any other make to this extent and it has great potential, ”explains Lindörfer. He was particularly impressed by the approach of the machine manufacturer from Oeynhausen. “Many manufacturers develop machine technology based on the trial & error principle. At Heesemann, mathematical methods were used to investigate which kinematics make it possible to work intensively on all edges and to round them,” continues Lindörfer. In addition, the tools are processed evenly over the entire working width so that it does not matter where the operator places the workpieces. These competitive advantages must now be further developed in a targeted manner and made known on the market.

Use synergy effects from wood processing

The Heesemann brand has so far been known primarily in the woodworking industry – as one of the major market and technology leaders in the field of industrial grinding machines. This experience and the possible synergy effects are now to be used in metal processing. “The prerequisites could hardly be better,” states Lindörfer. “The deburring machines, which are related in many respects, can be produced here efficiently. At the same time, Heesemann already has a worldwide network for service and spare parts supply,” says Lindörfer, summarizing the good starting position. This infrastructure and the existing know-how must now be used.

The fully modular profiRounder in focus

The first step in the collaboration has already been clearly defined. “The focus will initially be on the profiRounder. The fully modular system for dry machining of all metals can be perfectly adapted to the individual needs of various industries and therefore has great market potential,” explains Christoph Giese, managing director of Heesemann. The machine, which won the Red Dot Design Award in 2017, can deburr, round edges, remove slag and oxide and create a perfect surface finish as required. This makes it an extremely exciting product for companies in the metalworking industry that have a wide range of requirements for their grinding machine, says Giese. Making the benefits known is the first goal on the common agenda. “We are very happy that we were able to inspire Mr. Lindörfer for this exciting challenge and we are very much looking forward to working with him.”, the managing director looks positively into the future.