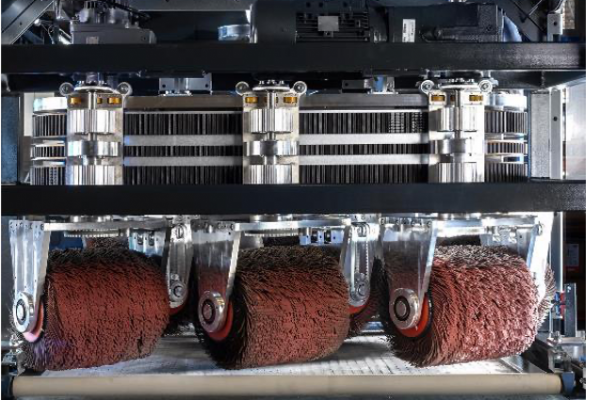

Blechexpo 2023: Perfect rounding with profiRounder by Heesemann.

The deburring and edge rounding system profiRounder is available in two variants

Source: Karl Heesemann Maschinenfabrik GmbH & Co. KG

Bad Oeynhausen, 19 October 2023

At a glance:

- Heesemann presents the profiRounder and profiRounder Impression deburring and edge rounding systems at the Blechexpo in Stuttgart.

- The profiRounder is capable of rounding workpieces with a level of uniformity unmatched by any other brushing process on the market.

- The systems achieve excellent material removal even at high feed rates, eliminating abrasive and energy wastage.

The Blechexpo international trade fair for metalworking draws visitors from all over the world to Stuttgart on November 7-10, 2023. Karl Heesemann Maschinenfabrik GmbH & Co. KG will have a booth in Hall 5 where it will exhibit two metal grinding machines from the profiRounder series. This year, the company is also presenting its two patented innovations, the KinematIQ and the RUL. These were ranked among the top 3 surface processing innovations at the last Blechexpo Awards and remain unequalled.

Heesemann’s specially developed KinematIQ software is capable of calculating the edge rounding of any brush unit on the basis of kinematics, enabling the development of perfect units. If a machine’s kinematic data is known, the intensity and uniformity of the rounding can be predicted down to the last detail. This creates major potential when developing new sanding units for rounding and deburring.

The RUL unit was developed with the help of the KinematIQ. This new system delivers intensive and uniform rounding with regard to both the geometry of the workpiece edges and the workpiece placement on the transport belt. The RUL unit consists of 6 revolving satellites, each of which carries a 370 mm wide and 350 mm diameter sanding lamella roller. The orbital motion of the satellites in conjunction with their rotation around both their vertical and horizontal axes processes the workpieces with equal intensity from all directions. Something which no other brushing process on the market achieves. The speed of the rotation, orbit and feed can be infinitely adjusted.

Ensures 100% uniform rounding: the RUL unit from Heesemann

The unique kinematics also enable the use of pressure rollers in addition to the vacuum to hold the workpieces on the conveyor belt. This is a unique advantage, particularly when working with long and narrow parts or warped workpieces. Classic “rotor” systems cannot utilize pressure rollers because the diameter of the rotors often exceeds 1,600 mm. In addition, this also makes the machines longer and also increases the feed time of the individual workpieces. With an overall length of just 1,000 mm, the RUL has very compact dimensions. An additional pressure roller is employed between the two tool paths and serves to securely hold long, narrow workpieces even if they are warped, for example.

“The new kinematics enable us to achieve outstanding results with homogeneous tool wear and unrivaled productivity. These innovations are not limited to the sheet metal sector but can also be adapted for use with software-based process optimization for woodworking. The RUL unit is now also available for the wood sector. Therefore, we have achieved one of our declared goals of creating synergies between these two divisions and to ensure knowledge transfer which our customers in both the wood and metal sectors can benefit from”, summarizes Managing Director Christoph Giese.

You can find Heesemann in hall 5, booth 5503.

Karl Heesemann Maschinenfabrik GmbH & Co. KG

Reuterstr. 15, 32547 Bad Oeynhausen

Phone +49 5731 188-0

www.heesemann.de

Press contact: Mrs. Cigdem Kurar, c.kurar@heesemann.de