Lacquer sanding and high-gloss production

Laquer sanding

The trend is clear – applied low quantities and stains and lacquers containing as little solvent as possible. For surface finishing UV lacquers with a high solids content, water based lacquers, waxes and low solvent stains are increasingly being used. Application quantities of markedly less than 10 g/m2 are no longer rare occurences.

Heesemann sanding machine technology has taken this development into account ready for the future:

- the infinite CSD® electromagnetic pressure regulation of the individual pressure elements in the pressure beam which permit an intensive but careful sanding of the endangered side, front and rear edges.

- the elastic pressure beam which optimally compensates for frequent tolerances within or between workpieces up to 2 mm max. without sanding through.

- the intermeshing pressure shoes which ensure gentle transitions on the surface and which avoid streakings.

- wide pressure beams for a uniform surface sanding attack.

- the frequency controlled sanding belt drives with a wide regulation range of 1:40, permitting the belt speed to be infinitely adapted to the individual lacquer and stain quality.

- servo drives allow minimum sanding belt speeds of 0.1 m/s.

- wide range of structuring and smoothening brushes for special finishing effects.

- thorough sanding belt cleaning, preventing sanding marks resulting from adhering dust grains.

- different interfaces serving as the prerequisite for linking into lacquer lines.

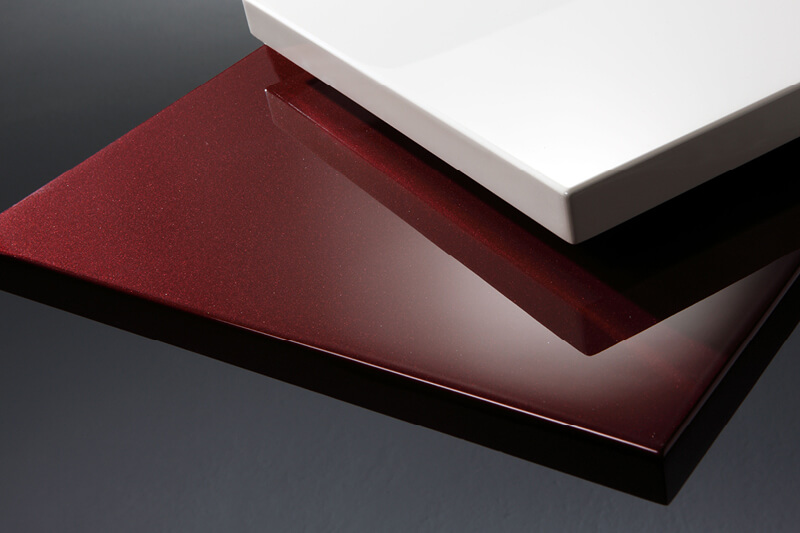

High gloss sanding

For high gloss surfaces the combination of cross and longitudinal sanding belts is established. Heesemann employs cross sanding machines here, with which even at fine grits a constant material teardown is effected and by cross sanding method a high quality surface is achieved. This technology results in a constantly plane surface.

High-Gloss production with a machine configuration C/L/C/C

When working with a machine with 3 cross units and 1 longitudinal sanding unit 3 to 4 passes through the machine are necessary for sanding raw MDF material up to the finished product if it is sanded with a grit of 600 or 800. If melamine-laminated MDF material has to be sanded the first working step could possibly be saved. The special advantage of a machine with 4 units is that no more than one pass through the machine in between the individual lacquering processes is required.

1st pass through the machine

If necessary (depending on the thickness tolerances of the raw material) calibration with activated calibration guide roller using a grit of 120. The cross units sand in the same pass through the machine with grits of 180 and 240 so that the workpiece is calibrated and sanded in one pass and is ready for lacquering.

2nd pass through the machine

Filler sanding with one cross, one longitudinal and one cross sanding unit e. g. with grits of 320, 360 and 400.

3rd pass through the machine

After applying base coat:

Lacquer sanding with all 4 units with a grit of 320 or 360 on the first cross unit, 400 on the longitudinal unit, 500 on the second cross and 600 on the third cross unit. For a final grit of 800 it is recommendable to sand with a grit sequence of 360/400/600/800.If at this stage already a top coat will be used as the substrate for polishing the grit sequence can be 600 / 800 / 1,000 / 1,200 prior to polishing.

4th pass through the machine

Depending on the type of used top coat and required final quality the top coat could be just polished or could be sanded with grits of 1,200 and 1,500 mm prior to polishing.