From trade to industry: Heesemann presents the entire spectrum of sanding at the LIGNA

Bad Oeynhausen, 10.04.2025

As the world’s leading trade fair, LIGNA not only stands for the global range of tools, machines and systems for woodworking and wood processing, but with its theme setting it is also regarded as a driving force for industry development. Tens of thousands of visitors from all over the world are once again expected in Hanover from 26 to 30 May 2025 to celebrate its 50th anniversary. In addition to four machines, the long-established sanding machine manufacturer Heesemann has plenty of innovations and solutions on board.

Focus on results

Automation, digital networking and intelligent product features that are tailored to customer requirements are the key themes at this year’s LIGNA. Ultimately, however, it’s all about the results that customers can achieve. That’s why Heesemann is focussing on solutions and customer references this year. High-quality floor coverings, exclusive pieces of furniture or customized applications from renowned manufacturers will find their place on the stand and invite visitors to discover the world of sanding. This will be rounded off with an example of automation that can also be realized in smaller companies at manageable investment costs. In addition to efficiency, the shortage of skilled labour is also one of the key issues of our time. Heesemann’s sanding experts show how the skilled trades can also automate their production easily and cost-effectively and position themselves efficiently and sustainably.

„Changing conditions in the global economy, the ubiquitous shortage of skilled labour, cost pressure and international competition pose major challenges, especially for traditional businesses and smaller craft enterprises. At Heesemann, we develop forward-looking solutions for our customers that they can implement easily and cost-effectively. This is our contribution to the sustainable and future-oriented development of Germany as a business location.“

Christoph Giese, Managing Director Karl Heesemann Maschinenfabrik

All signs point to the future with technical innovations

Technical innovation: Processing workpieces of different thicknesses in the same pass

Heesemann’s latest technology is celebrating a world premiere: high-speed height adjustment. The height of all units in the machine can be adjusted individually and independently of each other using separate drives. This individual height adjustment makes it possible to process different workpiece types and thicknesses in the same pass. The whole process takes place at no less than 25 mm/second, i.e. eight times faster than with conventional machine height adjustments. The high-speed height adjustment developed by Heesemann engineers is unique to date. The advantage is that parts such as fronts, frames and bodies no longer have to be processed separately by the sanding machine and downstream painting systems but instead are processed in the same pass. This eliminates time-consuming and costly sorting work, as parts of a complete kitchen, for example, can be picked together. This technology was first developed for an American kitchen manufacturer, reducing the throughput time from 2 minutes to 12 seconds, which enables enormous production efficiency.

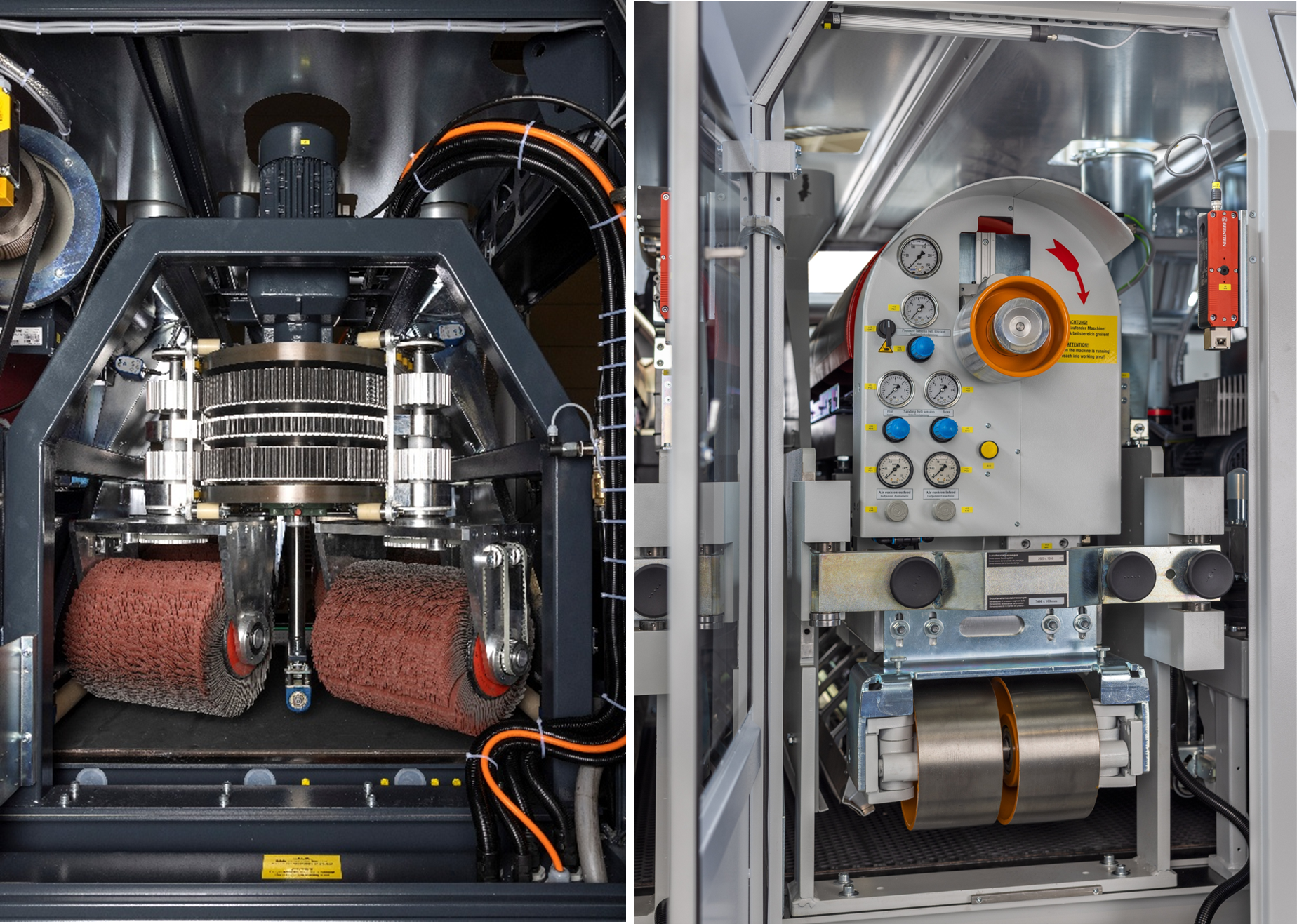

MFA 10 with RUL and OSR unit

The RUL lamella roller unit is Heesemann’s innovation that enables absolutely uniform edge breaking on all edges as well as the processing of very deep profiles. The RUL unit consists of 6 rotating satellites, each of which carries a 300 mm wide sanding lamella roller. The rotation of the satellites in conjunction with their rotation around both their vertical and horizontal axes means that workpieces are processed equally intensively from all directions, which no other brushing process on the market can achieve. Thanks to the unique kinematics, pressure rollers can be used in addition to the vacuum to fix the workpieces on the conveyor belt. This is a unique advantage, especially for long, narrow parts and workpieces with distortion.

With the OSR (Orbital Scratch Removal) Heesemann has another technical innovation up its sleeve that is of particular interest to overseas customers. When sanding frame parts or other workpieces with different grain directions, sanding against the grain direction cannot be avoided. The resulting sanding marks are clearly visible, especially when using dark-coloured stains. The OSR effectively removes all sanding marks. The stationary, vibrating sanding belt of the OSR unit removes the sanding marks from the upstream sanding machine. The result is an absolutely smooth surface, so that there are no differences in colour impression depending on the grain direction after staining. So far, the OSR has mainly been installed in machines for the American market, where there is a very high demand for so-called 5-piece doors. The technology harbours great potential for European furniture manufacturers who want to differentiate themselves from the competition with this application, which is not yet widespread on the domestic market.

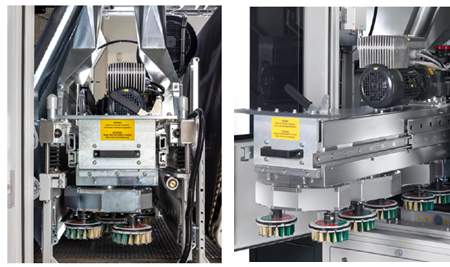

MFA Impression with DB-S disk brush unit

Equipped with a calibrating roller, a longitudinal and cross unit and the DB-S disc brush unit, the MFA Impression solves every conceivable sanding task: solid wood, veneer, lacquer and 3D surfaces can be processed. The MFA Impression is flexible and versatile, and appeals to both high-end craftsmen and industrial companies. The tried-and-tested DB-S disc brush unit ensures perfect sanding without oscillation marks and is flexible and versatile. The processing of three-dimensional surfaces, such as kitchen fronts with panels or workpieces with radii on the edges (e.g. doors, windows, table tops), as well as structuring, can be easily carried out with this unit. Another advantage that saves time and money: sharp workpiece edges are broken in the same pass, eliminating the need for additional manual work.

Model premiere JSM: The price and performance winner

The JSM is an affordable all-round machine for small and medium-sized craft businesses with high demands on surface quality. It is available in two sanding widths and three equipment packages. Depending on the package, it is ideal for solid wood, veneer and lacquer sanding. It offers an extremely good price-performance ratio and can be delivered in the shortest possible time thanks to the predefined configurations.

HSM: The surface sanding machine for the trade

The HSM is the customized surface sanding machine for the needs of small and medium-sized craft and industrial companies. Whether effect sanding, cross sanding, lacquer or high-gloss sanding, whether panels, solid wood or veneered workpieces – the Heesemann HSM is the perfect sanding machine for the trade and is particularly interesting for carpenters and interior fitters. The HSM is available in predefined standard configurations, equipped with two, three or four units and can be fitted with a cross belt for the cross sanding process.

SERVICE: Solution provider with the help of innovative service products

In addition to the technological innovations, Heesemann will be presenting a revised service portfolio at LIGNA that goes far beyond installation and spare parts. For example, customers can have existing systems retrofitted so that they can bring old machines up to the latest state of the art with the help of an electrical rebuild or open up new applications by replacing a unit without having to purchase a new machine. Virtual service calls allow problems to be solved in real time, application and technician training optimizes machine handling and helps customers to get the best out of their system.

Home match: Hannover – Bad Oeynhausen and back

Heesemann’s headquarters are based in Bad Oeynhausen, only a one hour drive from the fair. This is the perfect opportunity to combine a visit to the trade fair with a tour of Heesemann’s plant. Heesemann even offers interested customers a shuttle service to Bad Oeynhausen in the morning, ensuring that they get back to the fair by noon. To take advantage of the shuttle service, simply register online or directly with the booth’s staff beforehand.

Karl Heesemann Maschinenfabrik GmbH & Co. KG

Reuterstr. 15, 32547 Bad Oeynhausen

Phone: +49 5731 188-0

www.heesemann.de

Press contact: Mrs. Cigdem Kurar, c.kurar@heesemann.de