Innovations in grinding technology

In almost 100 years of company history, Heesemann has been one thing above all on the market for industrial grinding machines: innovation leader. Our engineers regularly developed technologies that gave our grinding machines a considerable head start. Many of these solutions have become industry standards – not only improving our own products, but also driving an entire industry forward.

This characteristic is an integral part of the corporate identity to this day. And with the increased commitment in the field of metal grinding, our bright minds have found a completely new playing field.

Heesemann has a long tradition of developing technologies that will permanently change the entire world of grinding. And traditions have to be cherished!

How do we want to contribute to conserving resources?

The Energy Management System is an energy-saving system that benefits both our environment and you. Reduced energy consumption reduces the burden our environment and reduces your costs. When no workpieces enter the sanding machine, the drive motors in the sanding units, which are designed with the highest energy efficiency class, reduce the speed and a flap on the extractor fan closes to greatly reduce the air flow rate. This significantly reduces the sanding machine’s energy consumption in accordance with the workload. When new workpieces arrive, all of the motors quickly start up again.

Our technologies

We do not simply want to sell you a sanding machine. Strictly speaking, the machine itself is only a means to an end. Our focus is on the excellent sanding results that you can achieve with a Heesemann. Maximum processing precision, short processing times and individually adaptable modules help you to optimize your product, make your processes more efficient and reduce your costs. With a Heesemann, you can improve your products while also boosting your productivity and your company’s success!

We see ourselves as an industrial manufactory. As such, we can offer you individually designed machine solutions with the benefits of industrial development and manufacturing processes. We intentionally maintain a high level of vertical integration in order to ensure the consistent quality of every single process step and also of the final result: Your own unique Heesemann.

No matter how customized your Heesemann may be, our machines all have one thing in common: we never compromise on any of the technologies we use. You will find the following standards in all our machines:

- All installed assemblies such as stands, transport tables, drums, rollers, etc. are manufactured in-house. Our mechanical production (welding, turning, milling) is designed for absolute precision and guarantees that the machine stand is torsionally rigid even when operated continuously and over decades. This ensures that deformations, vibrations or oscillations never occur and never a negative effect on the workpiece.

- All rotating assemblies are finely balanced: all rotating assemblies, whether rollers, drums or even the belt drive pulleys on the electric motors are fine balanced in-house. in the process, we guarantee that vibrations cannot negatively impact the sanding process

- Smoothly running units thanks to Poly-V belt drive: Not only rotating assemblies can induce vibrations. Ribbed belts also ensure that sanding units run exceptionally smoothly. In contrast to using multiple individual V-belts, these ribbed belts run with far less vibration. The speed-synchronized drive of both deflection rollers on the unit enables high power transmission together with low sanding belt tension. This enables a high degree of tolerance compensation via the pressure beam and ensures that the sanding belt can optimally adapt to handle warped workpieces and workpieces with high tolerances. Finely balanced rollers further optimize the machine’s smooth running.

- Compact machine design: The control cabinets are integrated in the machine housing and allow easy access even during operation. The terminals are mounted directly on the machine housing to save space. Electric motors are installed on the unit itself in the machine. This serves to maintain constant belt tension, independent of the thickness of the workpiece. The frequency converters are easily accessible in the machine.

- Modular system: Units can be replaced at any time and free spaces can also be equipped with additional units at a later date (as required). The same time, we can also adapt the machine length to these specific conditions at your premises.

- Machine stand: The machine stand is highly rigid due to its construction as a solid body and specific design details (similar to vehicle and aircraft construction). The machine stand also features noise insulation via a special coating on the machine stand, space-saving integration of the vacuum fan into the machine stand along with workpiece suction clamping channels integrated into the body, optimum air flow due to central position of the fan and short channel distances for workpiece suction without hose connections in the transport table (no risk of porous or torn hoses).

- Terminals/central machine operation: All of the machines are equipped with industrial PCs featuring color touchscreen terminals mounted in swivel housings enabling individual positioning of the industrial PCs. All of the machine functions are controlled from one location. The main menu page visualizes the machine. All of the relevant sanding parameters (sanding pressure, sanding belt speed, feed speed, edge pressure, etc.) are configured via a tabular chart.

- Abrasive belt cleaning and suction: Effective sanding belt cleaning is absolutely essential to achieve first-class sanding results and ensure a long service life of the sanding belts (along with the considerable cost reduction). Blow-off devices are controlled based on the specific workpiece. The abrasive belt itself is cleaned in the immediate vicinity of the drive roller rather than near the deflection rollers at the head of the units. Accumulating abrasive dust is extracted directly, considerably reducing the required extraction power.

- Workpiece cleaning in the machine outlet: Perfect workpiece cleaning is becoming increasingly important, especially for the thin-film coatings that are becoming more and more common today. Cleaning brushes for surfaces and edges are part of the machines’ standard equipment. In addition, non-contact compressed air rotors with a suction channel are available. The workpieces are often statically charged at the end of the machining process. This static charge can be discharged via an ionizing bar and the dust without static charge which remains after the ionizing bar is then cleaned off the surface via a rotating blowing unit at the end of the machine. This further contribute to reducing the energy consumption compared to the simplest compressed air blow-off equipment often found elsewhere.

- Safe workpiece transport: large pressure rollers in the infeed (optionally driven) for safe workpiece transport even with warped workpieces (optional), driven support rollers in the infeed and outfeed for safe workpiece transport on production lines (optional)

- Belt run protection and oscillation: dust-protected optical sensors protect against belt running and control abrasive belt oscillation. These operate without contact to protecting the material and require no maintenance. Simple adjustment of the belt center run control via a manual roller switch (Manutrace). The optional AutoTrace® belt center run control system automatically ensures uniform abrasive belt oscillation (LSM 8, MFA 10).

- Servo drives with water cooling: Water-cooled servo drives enable uniformly safe belt travel with maximum sanding performance and without speed fluctuations at minimum belt speeds of 0.1 m/s. Machines equipped with these servo motors are suitable for modern water-based coating systems, for example. The water-cooled servo drives are comparable with efficiency class IE 4

- Swivel supports: Swivel supports can be released with a single movement without tools. They serve as belt support aids for the operator, interfering edges are covered during belt changes and a special coating protects the sanding belts during belt changes.

- Maintenance-free pressure beams: the electromagnetic CSD® system is maintenance-free for its entire service life thanks to the closed pressure beams. In contrast to pneumatic systems, no contamination can occur from compressed air, oil or water.

- Easy accessibility: all maintenance elements are easily accessible. The top-mounted drives enable the poly-V belts to be easily replaced, checked or tensioned.

- Drive rollers: Maintenance-free bearings due to lifetime lubrication, optimum running smoothness due to punched grooves for seating the vibration-free poly-V belts (no attached pulleys), optimum running smoothness of the rollers – Heesemann running quality corresponds to balancing quality G 1 (for comparison: balancing quality G 40 is sufficient for car tires)

- Additional display on the machine outfeed: all parameters relevant for sanding, such as sanding pressure, belt speed, edge pressure, etc., can be adjusted immediately after the workpiece has exited the machine. The changed data is automatically transferred to the industrial PC on the machine infeed.

- Special doors: Door-in-door or door with glass insert available

- Workpiece detection via 3D laser scan: perfect stepless workpiece detection in the millimeter range cannot be achieved via a conventional mechanical switch battery (smallest division 16 mm). The new 3D LaserScan now enables detection of the workpieces in 1 mm segments. This allows even more precise adjustment of the pressure changes among the individual segments of the pressure beam

The optional HMI package equips your Heesemann with LED strips on the infeed and outfeed, optional camera monitoring on the machine outfeed along with status displays on the units. The LEDs have two key functions: On one hand, the strips utilize simple color symbols to indicate where the workpiece should be inserted in order to optimize wear on the sanding belts. For this purpose, the control system processes various parameters that the operator can adjust. This process immediately and significantly reduces your tooling costs by ensuring more even belt wear. On the other hand, warnings or errors are also displayed via the LED bars and communicated to the operator at the machine exit where the finished workpiece leaves the machine. This enables you to see from a distance if something is wrong. The additional strips on the operating side of the machine help you to easily locate errors. Optionally, your machine can also be equipped with an additional camera. The operator receives a live image of the outfeed on the terminal and can react immediately if, for example, a workpiece blocks the outfeed. Therefore, the HMI package gives you an additional measure of control and helps to sustainably improve the profitability of your processes.

Heesemann machines offer an interface for integration into the Homag Tapio system.

We create customized solutions with perfectly configured systems

Heesemann sanding machines serve a wide range of applications. Our mission is to provide the technology to meet your workpiece requirements and make your creative ideas and design concepts a reality. To fulfil our mission, we offer a wide range of units which our engineers can combine and adept to meet every customer’s unique requirements:

- Sanding and grinding units

- Calibration units

- Combined units

- Brush units

- Cleaning units (contact and contactless)

CSD-System

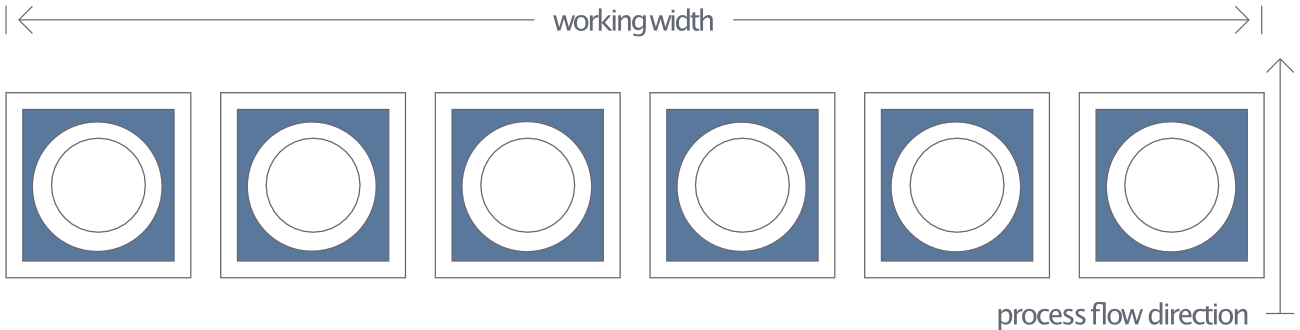

Our CSD magnetic pressure beam system has proven itself as a solution for adaptable grinding for more than two decades. The grinding result of a unit with a CSD system is still unmatched by other systems. The precise control of the sanding pressure is crucial for a high-quality and even sanding quality of the surface. With the computer-controlled selective pressure regulation of the CSD® magnetic pressure beam system, the grinding pressure on each individual element in the pressure beam can be continuously changed in milliseconds. A fine-grained scanning in the machine inlet provides the information for the exact pressure calculation. The elastic pressure beam effectively compensates for differences in the workpiece thickness within a workpiece or between several workpieces of up to 2 mm.

The pressure of the elements can also be controlled asymmetrically in order to increase the grinding force on one side. A typical application is the different design of the workpiece edges, e.g. B. by one-sided solid edge band. The pressure is applied by maintenance-free, current-controlled electromagnets. Contamination, as can occur with pneumatic elements, is excluded.

KinematIQ

The evenness and intensity of the edge rounding are two very important quality features of deburring machines. In many common processes, the edges are rounded to different degrees, depending on where the sheet metal workpiece runs through the machine. Only if the machine works with perfectly designed kinematics will all workpiece edges be machined 100% evenly.

In order to make our deburring machines technology-leading, we have developed a computer-aided process that can calculate and thus predict the uniformity and intensity of the results: Heesemann KinematIQ.

The principle behind this is simple: if the kinematics of the machine and tool are known, mathematical calculations can be used to precisely predict whether the rounding will be uniform or not.

Standardized test procedures have already validated these calculation results. This enabled every machine concept available on the market to be precisely evaluated and the Heesemann units to be optimized in detail.

The result: Unprecedentedly intensive and uniform rounding with homogeneous tool wear at the same time.

In practice, this process results in an enormous competitive advantage – both in the development of new and in the optimization of existing units. KinematIQ was used for the first time in the further

development of RUT technology.

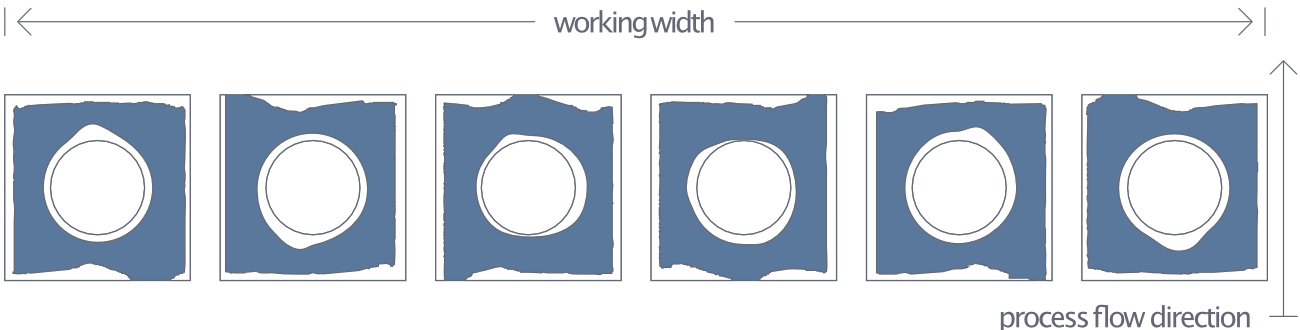

In order to visualize the results, the fillets are highlighted in the following graphics. The white areas do not represent the actual amount of material removed, but show the degree of unevenness, greatly enlarged.

The grinding result of a common planetary

head unit with two circular brushes per planet looks like this:

Planetary head unit with 2 disc brushes per planet

Experimental setup

Heesemann RUT unit