Further Information – possible aggregates

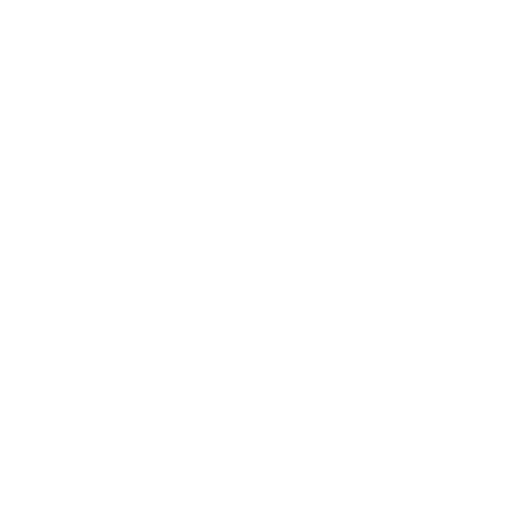

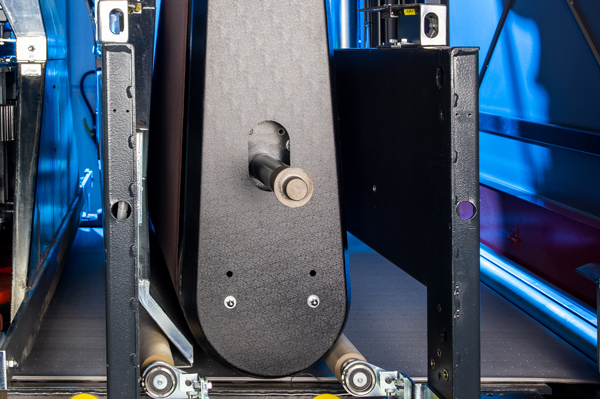

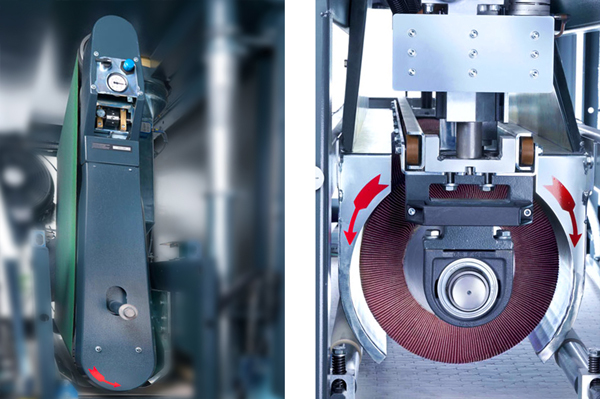

Unit for slag removal

With the use of slag chipping brushes, slag, dross and burrs can be removed economically and100% evenly on all workpiece edges!

The RUT unit impresses with its kinematics, because it ensures that all edges are processed equally frequently and with the same intensity from all directions. By using 18 disc brush tools, each with a diameter of 180 mm, the work results are generated at high feed speeds. Thus, the profiRounder impresses with its capacity and output!

See also: Deslagging

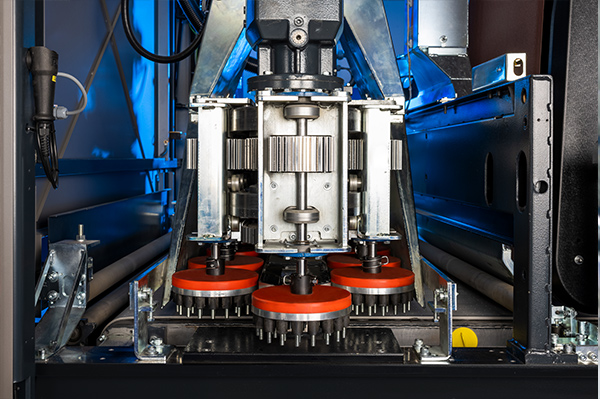

Unit for deburring:

In the profiRounder, the deburring process is performed with powerful grinding units. Contact rollers with a diameter of 250 mm and 300 mm are installed and are driven by motors up to 22 kW.

See also: Deburring

Unit for edge-rounding:

Edge rounding is redefined at Heesemann. Using a systematic approach, it was possible to develop a rounding unit that works with 100% uniformity. While many planetary heads and rotor systems deliver different and uneven results, depending on where a workpiece runs through the machine, the RUL unit achieves radii of 2 mm and more and this 100% uniformly on all edges of the workpiece regardless of their orientation. Depending on the application, also the RUT unit with deburring discs can be the right choice for rounding, giving you also 100% eveness with its 18 brushtools each Ø180mm diameter.

See also: Edge rounding

Unit for oxid removal:

With the use of cord wire brushes, oxide layers can be easily brushed off and this 100% evenly on all workpiece edges!

The RUT unit impresses with its kinematics, because it ensures that all edges are processed equally frequently and with the same intensity from all directions. By using 18 disc brush tools, each with a diameter of 180 mm, the work results are generated at high feed speeds. Thus, the profiRounder impresses with its capacity and output!

See also: Oxid removal

Units for surface finish:

When using the appropriate abrasive grains, the wide-belt unit can be used to create visually appealing, grinded surfaces. This is done either by converting the deburring unit to a finer grain size or, in the case of machines with an additional wide-belt unit at the outlet of the machine, by switching on the unit.

If particularly fine surfaces are to be produced, fleece lamellar rollers are often used, which produce particularly fine roughness depths on ground surfaces.

The units can be combined with one another as required and connected in series. This enables comprehensive machining of all kinds of workpieces. In this way, sheet metal made of steel, stainless steel, aluminum and other metals can be processed efficiently.

See also: Surface-Finish

Occupational safety through profiRounder deburring systems

Our deburring machines are not only optimized for maximum efficiency when deburring sheet metal. Occupational safety was also of crucial importance when designing the systems. The machines are fully encapsulated. This reduces the noise and prevents unauthorized access to the running system. The grinding dust is continuously extracted. This significantly reduces the amount of dust in the air. After all, our deburring machines are also equipped with a comprehensive safety concept. Accidental start-up of the machines during maintenance and cleaning work is thus excluded.

Material-Mix processing with profiRounder deburring systems

Practically all types of sheet metal can be processed on our deburring systems. Regardless of whether sheets made of stainless steel, steel or aluminum, foiled or galvanized material or parts with passages and embossings have to be deburred and rounded, our machines process everything with consistent quality and reliability. Thanks to the quick tool change, it is easy to switch between types of material.